Conventional plastic moulding

Conventional plastic moulding

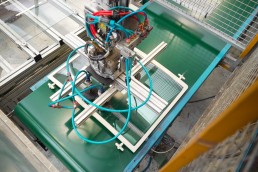

Conventional molding is used in the case of molding of single-component plastics.

Always up-to-date, it allows the realization of medium and small thickness artefacts. Traditional molding allows the production of objects with or without metal inserts, with customizable finishes.

Do you want more information?Call us at +39 0442 601700 or fill out the form

Our facilities

Products and sectors

- Furniture and Design

- Automotive

- Hydraulics, Conditioning, Water Treatment

- Consumer electronics

- Recycling

- Household products

Single component

Use single-component plastics

Versatile

Traditional molding

can be combined with other processes

Customizable

Suitable for every finishing option

Mold making

- Development and process engineering

- Ingegnerizzazione di prodotto e di processo

- Product and process engineering

- Rapid prototyping

- Design and realization of the mold project

Molding materials

ABS – PC – PA – PA6 – PA66 – PBT – PET – PPO – POM – PP – PPS and much more.

Other types of molding

Conventional molding is used in the case of molding of single-component plastics.

Assisted gas molding is suitable for the processing of products of any thickness and complex design.

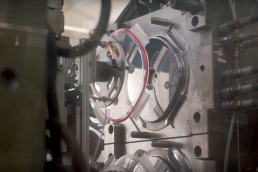

The two component-injection molding allows two different plastic materials to be used simultaneously inside the mold.

The innovative IML system (in moldlabelling) is a printing process that allows you to customize the product during the injection process by applying the decoration inside the mold.

It lightens products and optimizes molding costs

2.456

PRODUCTION SPEED

7867

DAILY PRODUCTION

48

PRODUCTION LINES

23.456

CUSTOMIZATIONS