Overmolding of metal inserts

Overmolding of metal inserts

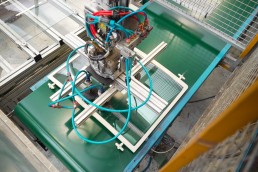

Co-molding is the injection of plastic components with metal inserts. This combines the cost reduction through plastic design with mechanical features offered by metal parts.

With this process we manufacture products like valves, knobs or gears.

The efficiency of our latest generation of presses and the automed allocation of metal parts in the mold allows fast processing, reducing production costs and optimizing production times, in oder to meet the needs of our customers.

Advantages of co-molding

- Processing speed

- Precision

- Cost optimization

Do you want more information?Call us at +39 0442 601700 or fill out the form

Our production

Products and sectors

- Automotive

- Hydraulics, Conditioning, Water Treatment

- Consumer electronics

- Domestic appliances

2K (Dual-component)

Produces objects with plastic and metal together

Versatile

Traditional molding

can be combined with other processes

Customizable

Suitable for every finishing option

Mold making

- Development and process engineering

- Ingegnerizzazione di prodotto e di processo

- Product and process engineering

- Rapid prototyping

- Design and realization of the mold project

Molding materials

ABS – PC – PA – PA6 – PA66 – PBT – PET – PPO – POM – PP – PPS and much more.

Other types of molding

Conventional molding is used in the case of molding of single-component plastics.

Assisted gas molding is suitable for the processing of products of any thickness and complex design.

The two component-injection molding allows two different plastic materials to be used simultaneously inside the mold.

The innovative IML system (in moldlabelling) is a printing process that allows you to customize the product during the injection process by applying the decoration inside the mold.

It lightens products and optimizes molding costs

2.456

PRODUCTION SPEED

7867

DAILY PRODUCTION

48

PRODUCTION LINES

23.456

CUSTOMIZATIONS